New construction of tank farms for aviation fuel

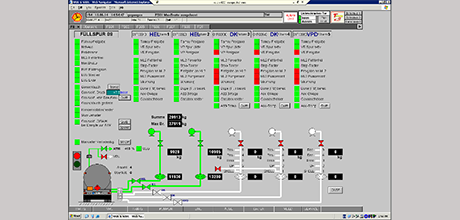

gat was responsible for the construction of two new tank facilities with underground storage tanks. This included unloading facilities for KWG and TKW, control and instrumentation technology including content and flow measurements in the pump house.